We power the industry

Our services include

Production of bearings and plain bearing shells

Reconditioning of bearings and plain bearings

Reconditioning and refurbishment of parts and components

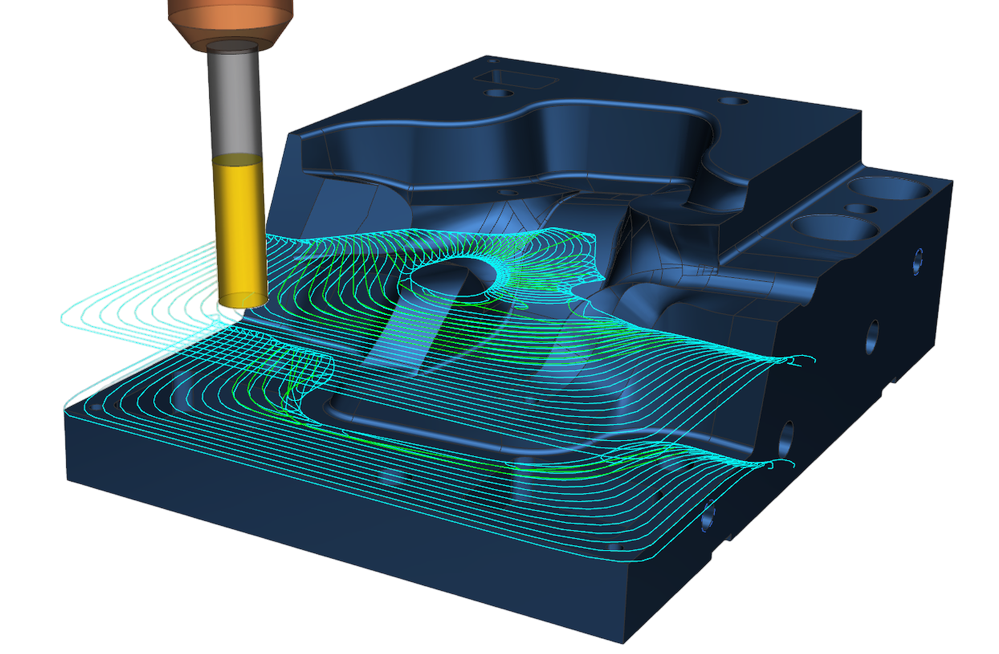

Production of parts according to design

Industries we help

We specialise in the production of slip pans for traction motors, which are key components in railway systems. We hold the PKP Intercity MMS Certificate of Conformity, which confirms the high quality and safety of our products.

We offer remanufacturing and manufacturing of marine components, including bearings, bushings and components for propulsion systems. Our products are tailored to industry standards, ensuring reliability and durability in harsh marine environments.

We supply key components for the energy industry, including turbines in power plants that efficiently produce energy. We also offer turbofans that improve air circulation and increase equipment efficiency. Our thrust segments provide stability and our hydrogen seals minimise the risk of failure in systems.

We manufacture high-quality parts for rolling mills and lunette grinders, which are key in metalworking. Our components ensure the reliability and efficiency of the processes, resulting in excellent product quality.

We create reliable components for internal combustion engines, including main and connecting rod shells that guarantee long-lasting performance. Our innovative solutions raise standards of quality and durability, providing engines with uninterrupted power and efficiency.

We manufacture industrial pump pan that excel in durability and performance. Thanks to advanced technology, our pan ensures smooth operation, which translates into efficiency of the entire system and a lower risk of failure.

We specialise in the manufacture of parts and components for a variety of industries, tailoring our solutions to the unique needs of each sector. Our products are used in a wide range of fields, allowing us to support growth and innovation across industries.

We offer innovative parts for equipment used in mines and mining operations that can cope with the most demanding conditions. Our components not only increase the efficiency of machinery, but also contribute to the safety and reliability of mining processes, which is crucial in this industry.

Equipment in refineries and oil processing plants

We manufacture advanced components for paper and press machines that support the efficiency of production processes in the paper industry. Our solutions are characterised by high quality and precision, enabling excellent results and minimising downtime, as well as improving the quality of finished products.

We create high-quality components for equipment used in food processing and production that ensure reliability and efficiency in every phase of the process. Our innovative solutions optimise productivity while meeting stringent quality standards.

We offer components for reactors, mixers and other process equipment that are essential in the chemical industry.

We overhaul turbine assemblies and manufacture components for the aerospace industry.

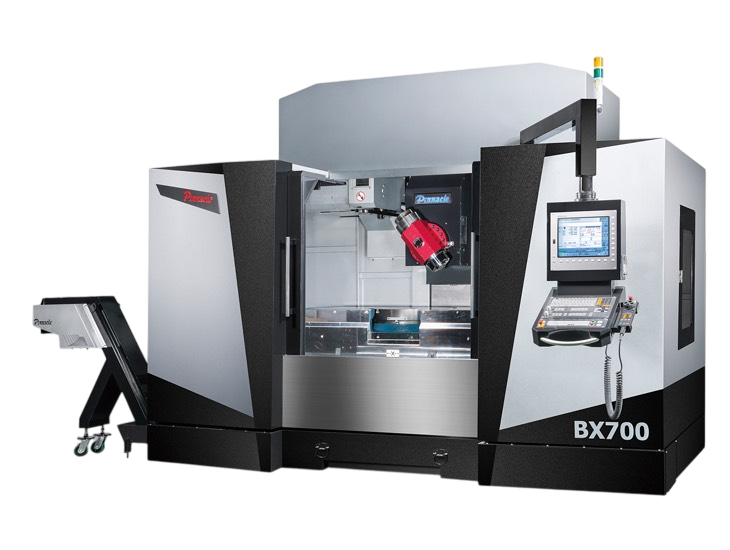

Modern machinery

We specialise in the manufacture of turbines and complex bearings requiring high precision.

Why Jurex Group?

From the foundry to the machining departmentevery stage of production takes place under our supervision

We have our own foundry

As a result, we create high-quality sliding layers tailored to demanding applications.

With us you can meet any industrial challenge!

Customised parts production

We are able to manufacture components with accuracy to 1/1000 mm and achieve a surface roughness level of 1/10.

Rapid order processing

Low logistical minimum

High precision manufacturing

Own foundry + Metal laboratory

Metal testing laboratory

Modern foundry department