Offer

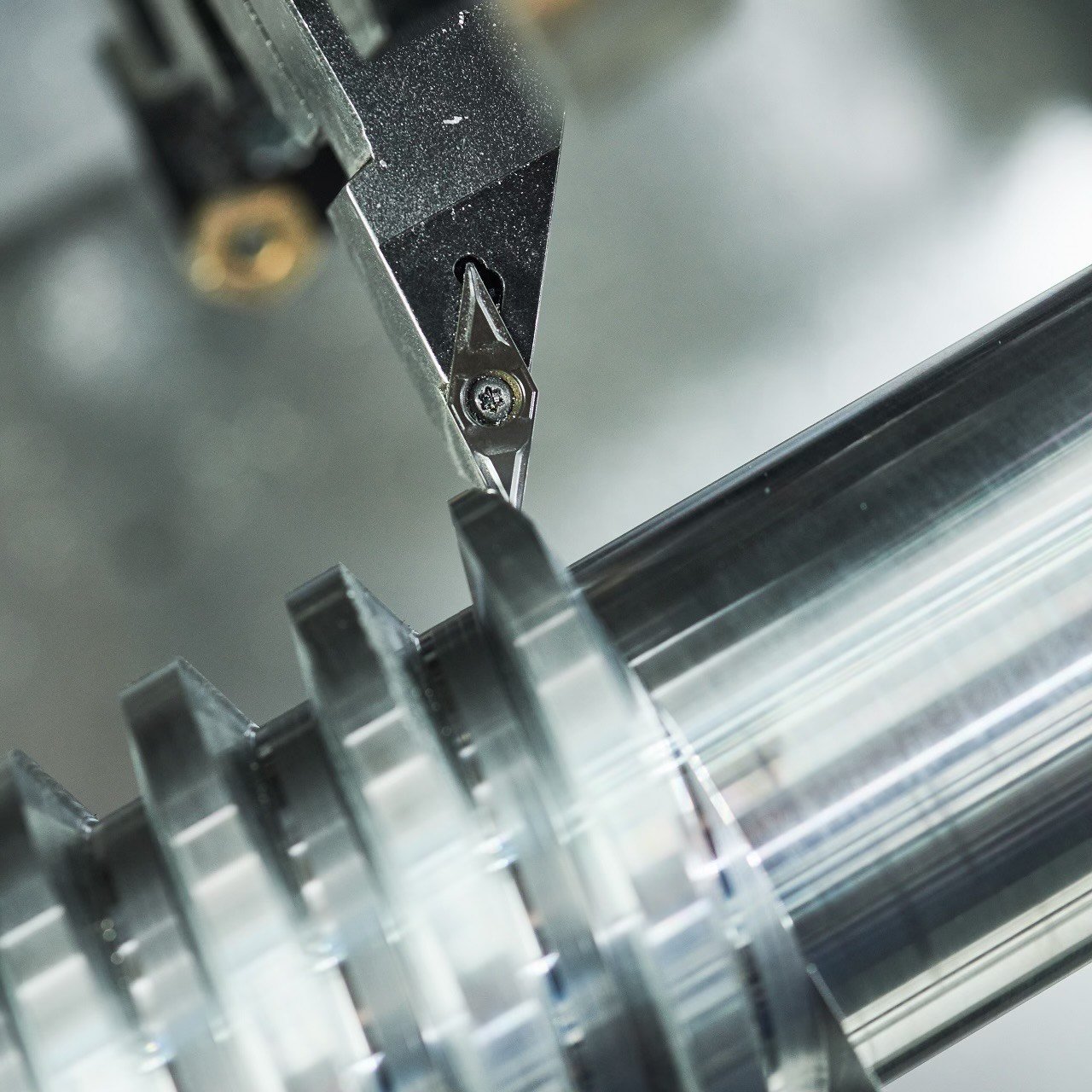

CNC lathe work

At Jurex Group, we specialise in precision turning work, offering comprehensive machining of metal components and more. Our services include turning, threading and forming, allowing us to carry out complex projects tailored to specific customer requirements. Thanks to our modern machinery, we ensure high quality, repeatability and on-time delivery.

Renovations

Precision and quality at every stage

Thanks to the advanced technologies and experience of our staff, turning work at Jurex Group guarantees a perfect finish and high dimensional accuracy. We treat each project individually, allowing us to optimally adapt to our customers' needs and technical specifications.

Precision lathes for machining workpieces with complex shapes.

Advanced industrial robots to support process automation.

Capable of delivering projects with tolerances of up to 0.004 mm.

Wide range of turning services

Our turning services include the turning of parts of various shapes and sizes, including both single parts and batch production. We are able to complete projects for a variety of industrial sectors.

Adaptation to individual needs

Each order is analysed in terms of specific requirements, allowing for projects of varying complexity. Our team of engineers and technologists work to deliver solutions that are perfectly tailored to our customers' expectations.

High production efficiency

Thanks to the use of modern machinery and processing technology, we are able to process orders quickly and efficiently, which contributes to minimising waiting times for finished products. This increases the efficiency of our customers' production processes.

Additional information:

What are plain bearings and what are their uses?

Plain bearings are machine components used to transfer loads while minimising friction. They are used in heavy industry, automotive, construction and specialised machinery where reliability in harsh operating conditions is key.

What are the main types of plain bearings offered by Jurex Group?

Our offer includes:

1. Spherical plain bearings requiring lubrication - ensuring a long service life through regular maintenance.

2. maintenance-free plain bearings - eliminating the need for frequent lubrication, ideal for applications requiring minimal service intervention.

3. deep-groove plain bearings (steel on steel) - characterised by high resistance to shock loads and alternating directions of operation.

What materials are used to manufacture plain bearings?

Depending on the type and application of the bearings, we use different combinations of materials, including hardened sliding surfaces, lubricants with molybdenum disulphide (MoS₂) and phosphate coatings for increased wear and corrosion resistance.

What advantages do plain bearings offer over other bearing types?

Plain bearings stand out:

1. resistance to high dynamic and static loads.

2. ability to operate in harsh environmental conditions (dust, humidity, high temperatures).

3. lower maintenance requirements (for maintenance-free models).

4. adaptation to oscillating and tilting movements

1. resistance to high dynamic and static loads.

2. ability to operate in harsh environmental conditions (dust, humidity, high temperatures).

3. lower maintenance requirements (for maintenance-free models).

4. adaptation to oscillating and tilting movements

What are the maintenance recommendations for plain bearings?

For bearings requiring lubrication, it is recommended:

1. Regular use of appropriate lubricants.

2. wear monitoring and periodic maintenance.

3. Ensure appropriate operating conditions to extend bearing life.

Does Jurex Group carry out bespoke projects?

Yes, we offer the possibility of customising bearings to individual customer requirements. Our state-of-the-art machinery allows us to realise projects with tolerances down to 0.01 mm.

What are the standard tolerances in plain bearing manufacture?

Thanks to our advanced manufacturing process, we are able to achieve tolerances of up to 0.01 mm, ensuring high precision and reliability of our products.

How do I order plain bearings from Jurex Group?

To place an order or for more information, please contact us by phone or email. Our team of technical advisors will help you select the right solution to suit your needs.